Unlike traditional paint, “ultra-white” paint is made from a chemical compound called barium sulfate, which is also used in the production of cosmetics and photographic paper.

Barium sulfate particles are made up of different sizes, which “disperse” the sun’s rays and can even cool the immediate surrounding surfaces.

White paint has been used for centuries in warmer climates to cool buildings from the heat, The researchers said this new formula absorbs much less sunlight and therefore heat.

An image from the infrared camera shows how a sample of the new ultra-white paint cools the surrounding area. The image on the left shows the paint in situ, while the one on the right uses special technology to show how it cools the surrounding area. The darker the color, the lower the temperature. Credit: Purdue University / Joseph Peoples

While normal paint will absorb between 10 percent and 20 percent of sunlight, the new paint only takes up 1.9 percent, an amount small enough to allow a building to lose heat overall, they said..

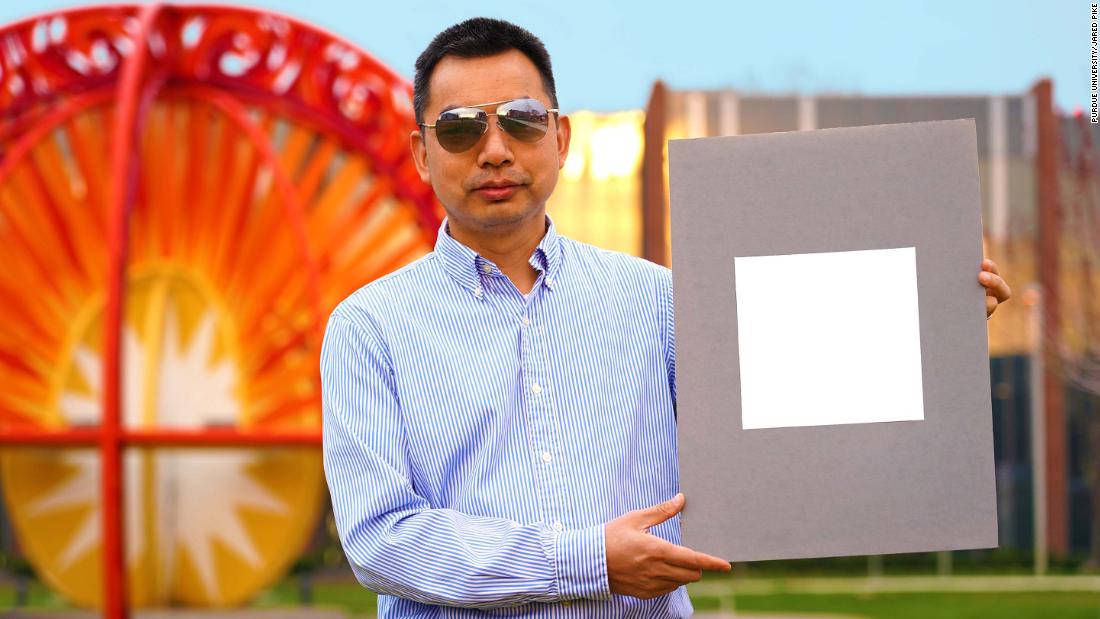

“If you used this paint to cover a ceiling area of about 1,000 square feet, we estimate you could get a cooling power of 10 kilowatts. It’s more powerful than the central air conditioners that most homes use,” he said. say principal investigator Xiulin Ruan, a professor of mechanical engineering at Purdue.

It is the “coolest recorded,” they claimed, able to keep 19 ° Fahrenheit surfaces colder than other night environments and 8 ° Fahrenheit lower during strong sunlight.

Lukas Schertel, a light scattering expert at Cambridge University who did not participate in the research, told CNN that the findings were potentially exciting and that the paint, if used on an industrial scale, could have a positive impact. on the climate by reducing energy consumption.

He said research on refrigeration paints had gained momentum in recent years and that if applied on an industrial scale, including generators and other heat-radiating machinery, in theory “could have an overall impact on energy efficiency.” .

The challenge would be to encourage commercial adoption, he said, and to do so, paint manufacturing should be scalable and affordable.

The materials used in the formula are already “relatively widely available,” he added, but one manufacturer “should make it cost-effective.”