The Baltimore plant contracted to manufacture the Johnson & Johnson vaccine against the counter-19 was dirty, did not apply production protocols and its staff was not trained, which resulted in contamination of the material for the injections, US regulators revealed today.

The Food and Drug Administration (FDA) issued a report on its recent inspection of the Emerging Biosciences factory, production was halted.

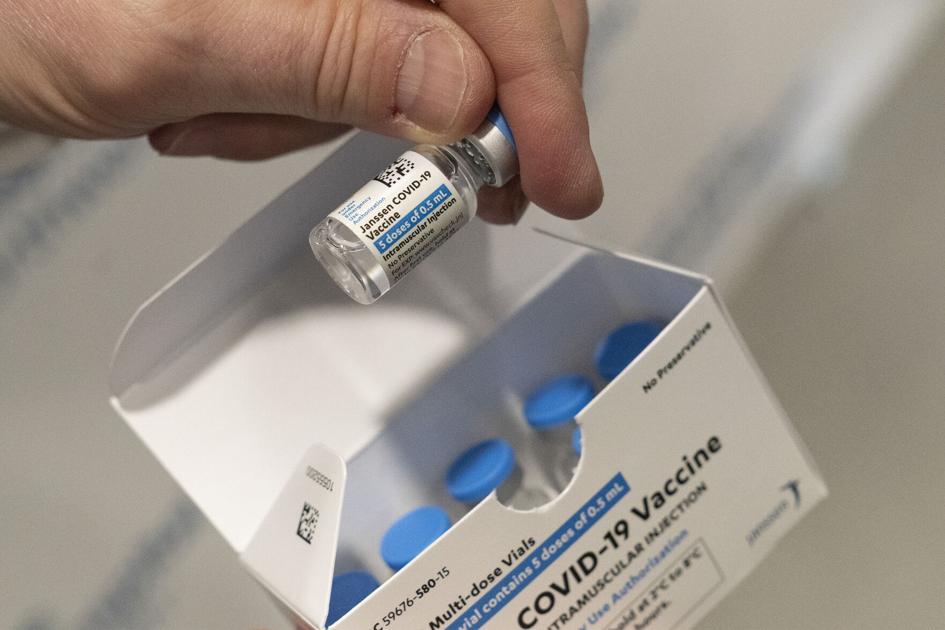

Inspectors said a batch of the substance used for the J&J vaccine, which requires a single injection, was contaminated with material used for another company’s client’s covid-19 vaccines. AstraZeneca. It was necessary to reject this whole lot, which according to the report was enough to manufacture about 15 million doses of the J&J vaccine.

The report mentions other problems, such as peeling paint, black and brown debris on floors and walls, poor cleaning and employees not applying the protocols to prevent contamination.

Emergent and Johnson & Johnson said today that they were trying to solve the problems with the utmost urgency. So far none of the products manufactured there by J&J had been distributed.

The use of the J&J vaccine is on hold in the United States for the time being as authorities investigate its relationship to certain very rare blood clots. Nearly eight million doses of this vaccine, from Europe, were used.

The Baltimore plant stopped production late last week on FDA orders. The agency has not given emergency permission to the factory, which is necessary for its products to be distributed.

The FDA said the substance produced by Emergent is in storage, pending further testing.